Researchers Weave Silver Into Protective Masks

New process could improve protection and extend the lifespan of critical protective equipment

Researchers Weave Silver Into Protective Masks Heading link

In the early days of the COVID-19 pandemic, personal protective equipment, particularly medical-grade masks, were in such short supply that they were metaphorically worth their weight in gold and silver. Two-plus years into the pandemic, supplies have increased, but there is still a demand for high-quality and reusable masks to help protect health care workers and populations across the globe.

Richard and Loan Hill Biomedical Engineering Department Professor Christos Takoudis, with Professor Cortino Sukotjo from the College of Dentistry and their colleagues, investigated new ways to create N95 masks that are highly protective and retain that protective ability even after having been washed, so they can prolong their lifespans and cut down on costs. And they did so by spinning in tiny pockets of silver.

Traditionally, most N95 masks are made of a material called polypropylene; a synthetic plastic fiber found in items such as rain jackets, yoga pants, and stretchy fabric. They also can include other materials such as aluminum, polyurethane, steel, and rubber.

Researchers Weave Silver Into Protective Masks Heading link

Sukotjo explained that washing masks with water, soap, and alcohol is not recommended, since it may reduce particle filtration efficiency significantly, leading to lower protection for the wearer. Recent research has found that masks can be cleaned using vaporized hydrogen peroxide or ultraviolet irradiation, but many people and private practitioners do not have access to the facilities that perform these decontamination procedures.

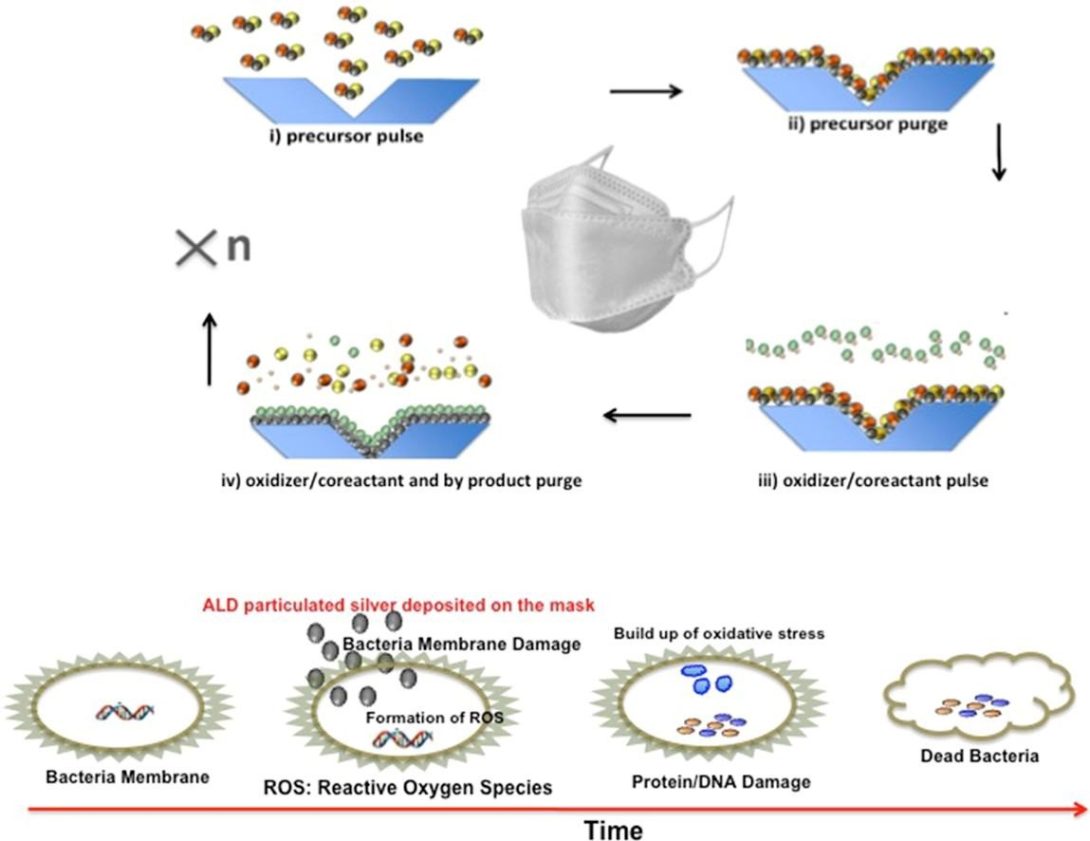

In this study, the scientists used a patented version of a technique called atomic layer deposition to imbed the filter of an N95 mask with tiny nano-islands of silver. They then exposed the masks to antimicrobial tests, finding a 76% reduction in bacteria content after 24 hours of biofilm development on the mask surfaces.

The study showed there is far less concern about likely toxicity with the use of the novel nano-islands versus different techniques for adding silver to a mask, Takoudis said. They also found there was strong bonding of the nano-islands onto the N95 mask materials, and the antimicrobial effectiveness of mask materials was seen with a robust number of silver nano-islands.

“Based on our preliminary results, it does not seem to be difficult to have silver nano-island treated masks that can indeed stand up to being washed and still maintain its protective ability,” Takoudis said.

Takoudis pointed out that although this effort was focused on substantially improving the antibacterial and antiviral functionalization of N95 masks, it has the potential of being used with other kinds of masks, too.

“The study may increase the lifetime and effectiveness of antibacterial/antiviral masks which may be beneficial for practitioners working anywhere in the world and in particular in developing countries,” Takoudis said.

The researchers published their new observations in the journal Applied Surface Science in a paper titled “Is atomic layer deposition of silver possible on N95 masks?”

The work was the result of collaborative efforts of researchers who, besides Cortino Sukotjo, included Gregory Jursich in the UIC Chemistry Department and Valentim Adelino Barao from the University of Campinas at Sao Paulo. This research also included doctoral students, including lead researcher Sarah Hashemi Astaneh, who has since graduated and joined the Intel Corporation.

Credit: David Brazy, UIC College of Engineering